Preserving History

Preserving a Historical Landmark

Built as part of St. Augustine’s first power and ice complex in 1907, we have lovingly restored and brought this piece of history back into service so it can serve the community for the next century.

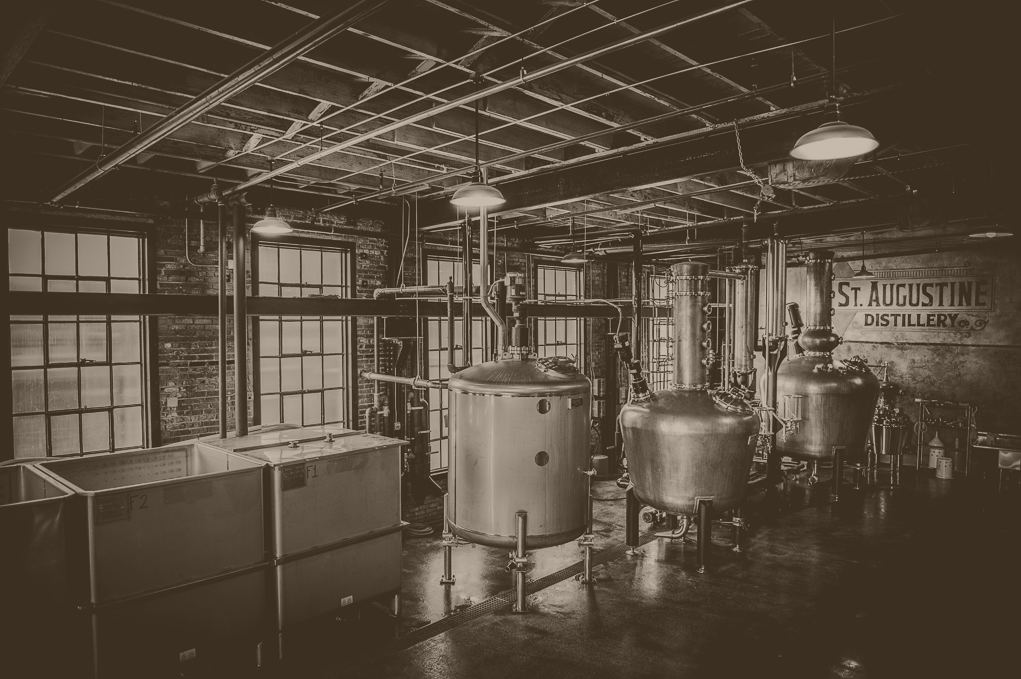

Finding a home with lots of soulful character that would be big enough to house a working distillery – while also being convenient to visit – was no small task. There was one building that had everything we needed: The Historic FP&L Ice Plant. Built as part of St. Augustine’s first power and ice complex in 1907, we have lovingly restored and brought it back into service so it can serve the community for the next century. The Ice Plant is a contributing building to the Lincolnville neighborhood on the National Register of Historic Places and was the first of it’s kind to make commercial block ice in Florida over 100 years ago. Today, it is helping us make Florida’s first bourbon and other fine, craft spirits. We love our home and hope you will too.

The History of Ice Production

In the beginning...

The St. Augustine Distillery has the good fortune to be the new steward of the Ice Plant, a building with vital history in the community. This is one of four original buildings that produced power and ice for St. Augustine. The first of the buildings was a power plant built in 1905 to provide power for the city of St. Augustine. The other buildings were constructed over the next two decades as the city grew.

Keeping St. Augustine Cool

Ice production began in St. Augustine in 1886. By the early 20th century, St. Augustine’s 20,000 residents used 125 tons of ice a day. Shrimpers and farmers needed ice for shipping. The Ice Plant was in production 24 hours, 7 days a week.

Ice Production

Steam turbines power generators to produce electricity.

The electricity powers a compressor that turns ammonia gas (the refrigerant into high-pressure vapor.

The ammonia gas vapor feeds into a condenser where it turns into a high-pressure liquid.

The chilled liquid ammonia is piped into the ice can tank.

Water filled ice cans are frozen by the highly pressurized ammonia liquid below.

Ice blocks are ready for “pulling” in about 48 hours.

Transporting the Ice

Large cranes were used to “pull” the ice cans. The largest ice cranes could pull 13 cans at a time. The cans were immersed into a water bath to loosen the ice from the can and emptied.

Walking on Ice

Cypress wooden tops covered these ice cans in the removable floor. Each can held 39 gallons of water or 325 pounds of ice. The empty cans were refilled and placed back into their slots. Numbers on the iron rails above the tanks helped the iceman know which can rows to pick next. You can see these numbers in the building today on your tour of the Distilling area.

Preservation Awards & Acknowledgments

2014 Award for Excellence for the Reuse and Repurpose Sector by the Urban Land Institute of North Florida

2015 Regional Award for Excellence in Culture, Historic Preservation or Adaptive Reuse, Northeast Florida Regional Council

“How The St. Augustine Distillery Put History On Ice”

- Folio Weekly

2014 Adelaide Sanchez Award for Historic Preservation, Restoration, Education and Interpretation